La multinazionale Airbus ha annunciato una nuova versione da combattimento, attacco elettronico (ECR) e soppressione delle difese aeree nemiche (SEAD) dell'Eurofighter Typhoon.

Il nuovo progetto è stato presentato per la prima volta durante l' Airbus Trade Media Briefing (TMB) il 5 novembre e poi il 12 novembre durante l' International Fighter Conference.

La configurazione presentata da Airbus mostra il Typhoon che trasporta due Pod Escort Jammer, tre serbatoi di carburante da 1000 litri e sei missili aria-terra MBDA SPEAR-EW (attualmente in fase di sviluppo per la Royal Air Force), oltre allo standard air-to -air loadout di quattro Meteor e due IRIS-T. Alcune fonti descrivono anche la capacità di utilizzare i missili anti-radar AGM-88B HARM e AGM-88E AARGM. Gli Escort Jammer Pods saranno integrati da due sistemi di localizzazione di emettitori installati sulle estremità alari del Typhoon. Secondo un'infografica fornita da Airbus, sarà possibile combinare jammer di scorta e stand-in sullo stesso aereo.

L'Eurofighter ECR / SEAD sarà "quasi certamente" un aereo biposto con un ufficiale di guerra elettronica sul sedile posteriore. Il cockpit anteriore e posteriore saranno indipendenti l'uno dall'altro e l'EWO avrà un display touch panoramico multifunzione e un cockpit di missione dedicato a sua disposizione per eseguire la missione Electronic Warfare / Electronic Attack.

La capacità operativa iniziale per la nuova versione dell'Eurofighter ECR è prevista entro il 2026, mentre la piena capacità sarà implementata entro la fine degli anni '20 nei nuovi telai costruiti come standard del programma di evoluzione a lungo termine. Le nuove tecnologie saranno ulteriormente sviluppate e completamente integrate nel Future Air Combat System (FCAS). Si raggiungerà una transizione senza soluzione di continuità in FCAS sfruttando il potenziale delle tecnologie odierne e sfruttando il loro potenziale di crescita. E l'Eurofighter ECR è un perfetto esempio di questo potenziale.

Secondo Airbus, il concetto di Eurofighter ECR si rivolge specificamente ai requisiti dell'aeronautica tedesca per una capacità di attacco elettronico aereo per sostituire l' ECR Tornado della Luftwaffe, anche se ciò non è stato ancora confermato dal Ministero della Difesa.

Attualmente, l'unico velivolo SEAD dedicato in Europa (senza considerare il blocco USAFE F-16CM Block 50) è il Tornado ECR, che verrà ritirato nei prossimi anni.

Airbus e i suoi partner hanno presentato per la prima volta dettagli concreti sul nuovo concetto di caccia da combattimento elettronico Eurofighter (ECR).

Questa nuova versione amplierà le capacità multiruolo dell’Eurofighter e aumenterà ulteriormente la capacità di sopravvivenza delle forze della coalizione occidentale in ambienti ostili.

Le capacità di collaborazione in materia di guerra elettronica sono essenziali per le future operazioni aeree combinate.

La capacità iniziale dell’Eurofighter ECR dovrebbe essere operativa entro il 2026, seguita da ulteriori fasi di sviluppo e dalla piena integrazione nei futuri sistemi del futuro caccia stealth di 6^ gen. FCAS.

L'Eurofighter ECR sarà in grado di fornire una localizzazione passiva dell'emettitore e l'interferenza attiva delle minacce, e offrirà una varietà di configurazioni modulari per l'attacco elettronico (EA) e la soppressione/distruzione delle difese aeree nemiche (SEAD/DEAD). La più recente tecnologia disponibile di escort jammer garantirà il controllo su elementi quali i dati della missione e l'analisi dei dati. Il concetto comprende anche una nuova configurazione del cockpit biposto con display panoramico touch screen multifunzione e un cockpit di missione dedicato per i sedili posteriori.

Il concetto è guidato dalle principali aziende aerospaziali Airbus, Hensoldt, MBDA, MTU, Premium Aerotec, Rolls-Royce e supportato dagli enti nazionali tedeschi dell'industria BDSV e BDLI. L'obiettivo specifico è quello di soddisfare i requisiti della Luftwaffe per la capacità di attacco elettronico. Inoltre, è l'unica opportunità di fornire tali capacità su base nazionale, garantendo al tempo stesso la sicurezza delle tecnologie militari chiave all'interno della Germania.

Attualmente l’Eurofighter è la spina dorsale della difesa aerea tedesca. Con oltre 600 velivoli sotto contratto e una forza lavoro di 100.000 dipendenti, è il più grande programma di difesa collaborativa in Europa fino ad oggi.

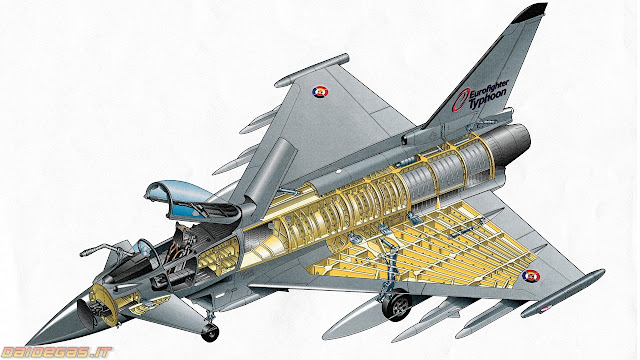

L'Eurofighter Typhoon, il cui prototipo era designato EFA (European Fighter Aircraft), è un velivolo multiruolo (Swing Role) di quarta generazione, bimotore, con ruolo primario di caccia intercettore e da superiorità aerea.

Progettazione e produzione del Typhoon fanno carico a un consorzio di tre società, Alenia Aermacchi (confluita in Leonardo, nuovo nome di Finmeccanica dal 2017) Airbus Group e BAE Systems, attraverso una holding comune, Eurofighter GmbH, costituita nel 1986. Il progetto è gestito dalla NETMA (NATO Eurofighter and Tornado Management Agency), che agisce anche come primo cliente.

Lo sviluppo del velivolo è iniziato nel 1983 con il programma Future European Fighter Aircraft, una collaborazione multinazionale tra il Regno Unito, Germania, Francia, Italia e Spagna. A causa di disaccordi sulle autorità costruttive e funzionali, la Francia ha lasciato il consorzio per sviluppare indipendentemente il Dassault Rafale. Un primo aereo di dimostrazione tecnologica, il British Aerospace EAP (Experimental Aircraft Programme), ha effettuato il primo volo il 6 agosto 1986; il primo prototipo dell'Eurofighter ha invece avuto il battesimo del volo il 27 marzo 1994. Il nome del velivolo, Typhoon, è stato formalmente adottato nel settembre 1998 e nello stesso anno sono stati firmati i primi contratti di produzione.

Questioni politiche avvenute nei paesi partner hanno causato il protrarsi in modo significativo dello sviluppo del velivolo; la fine improvvisa della Guerra Fredda ha ridotto la domanda europea di aerei da combattimento e mancavano accordi sulla condivisione dei costi e sulla divisione della produzione. Il Typhoon è stato introdotto in servizio operativo nel 2003. Attualmente, al 2015, è in servizio presso le Forze aeree austriache, l'Aeronautica Militare, l'Aeronautica militare tedesca, la Royal Air Force, l'Aeronautica Militare Spagnola e la Royal Saudi Air Force. L'Aeronautica Militare Reale dell'Oman ha confermato la volontà di acquistarne alcuni esemplari, portando il totale di aerei venduti a 571 aeromobili al 2013.

L'Eurofighter Typhoon è un velivolo estremamente agile, progettato per un combattimento aria-aria estremamente efficace contro altri aeromobili, ed è stato descritto come secondo solo al F-22 Raptor e al F-35 Lightning 2 tutti e due statunitensi e di quinta generazione anche se il Raptor e l'F-35 costano quasi il doppio. In seguito, i velivoli prodotti hanno beneficiato di diverse migliorie, come attrezzature atte ad intraprendere missioni di attacco aria-superficie e la compatibilità con un numero altrettanto crescente di diversi armamenti ed equipaggiamenti, tra cui il missile da crociera SCALP e il Brimstone della RAF. L'aereo ha visto il suo debutto in combattimento durante l'intervento militare in Libia del 2011 con la Royal Air Force e l'Aeronautica Militare, eseguendo missioni di ricognizione e bombardamento a terra. Il Typhoon ha anche assunto la responsabilità primaria per le funzioni di difesa aerea per la maggior parte delle nazioni coinvolte nel progetto.

I primi velivoli di questo tipo sono entrati in servizio, nell'Aeronautica Militare, presso la base aerea di Grosseto, tra le file del 4º Stormo caccia, il 20 febbraio 2004. In AMI la denominazione ufficiale è F-2000A per i monoposto e TF-2000A per i biposto.

Storia

Inizialmente i membri del consorzio internazionale che avrebbe portato al Typhoon erano Regno Unito, Germania, Italia, Spagna e Francia, che nel 1985 ne uscì per sviluppare in proprio il progetto: l'ACX, cioè il Rafale.

Il lavoro fu diviso: 33% per la British Aerospace, 33% per la DaimlerChrysler Aerospace (DASA) tedesca, 21% per Alenia Aeronautica e 13% per la CASA spagnola. Tuttavia al momento della firma dell'ultimo contratto, le quote furono il 37%, 29%, 20% e 14%.

Il 2 luglio 2002 il governo austriaco annunciò la decisione di acquistare Typhoon, ma il contratto non fu firmato per cause legate alla politica interna del Paese.

L'affare fu concluso un anno dopo per un costo di 943 500 000 €: fornitura di 15 aerei, addestramento di piloti e tecnici, logistica, manutenzione, un simulatore, per un costo unitario di 62 900 000 €.

Il nome del progetto ha subito numerosi cambiamenti: da EFA (European Fighter Aircraft), Eurofighter, EF2000 e infine Typhoon.

Nell'Aeronautica Militare

È uno degli aerei in dotazione all'Aeronautica Militare, che ne ha dichiarato la «capacità operativa iniziale» e lo ha immesso in servizio d'allarme il 16 dicembre 2005. Il primo reparto ad averlo in dotazione è stato il 4º Stormo Amedeo D'Aosta con base a Grosseto; l'arrivo del primo esemplare fu il 16 marzo 2004. Il Typhoon ha sostituito gli ultimi F-104S come caccia per superiorità aerea, nonché i Tornado (nella versione ADV) ed i caccia F16.

Gli esemplari acquistati sono 96, (82 monoposto + 14 biposto). Un F-2000A (MM7278/RS-23) appartenente al Reparto Sperimentale di Volo, si è schiantato in mare il 24 settembre 2017 a largo di Terracina durante un'esibizione, morto il pilota. Ne sono attualmente in servizio 73 come caccia intercettore e 12 in configurazione d'addestramento. Sono in dotazione al 4º Stormo di Grosseto, al 36º Stormo di Gioia del Colle (Bari) ed al 37º Stormo di Trapani Birgi.

Descrizione

Il Typhoon adotta una configurazione aerodinamica con ala a delta e alette canard a calettamento regolabile, come numerosi altri caccia recenti. Questa configurazione esalta la stabilità longitudinale a velocità subsonica e, grazie a un sistema di controllo digitale fly-by-wire della stabilità, garantisce elevata maneggevolezza nel combattimento manovrato a distanza ravvicinata. L'ottima combinazione di agilità e avionica comprendente anche il nuovo sistema Euroradar CAPTOR lo rendono attualmente uno dei velivoli più efficienti. Ha una RCS frontale pari a 0,5 metri quadrati, dunque è considerato semi-stealth. Una versione per portaerei è stata proposta dal consorzio Eurofighter all'India.

Produzione

Una caratteristica particolare dell'Eurofighter è quella di essere l'unico aereo militare moderno costruito in quattro linee di montaggio diverse, al contrario dell'F-16 che è semplicemente prodotto al di fuori degli Stati Uniti sotto licenza limitata. I quattro Paesi che hanno dato origine al progetto, infatti, producono componenti comuni a tutti gli esemplari ma sono responsabili dell'assemblaggio finale dei propri velivoli.

ENGLISH

At the International Fighter Conference in Berlin Airbus and its partners introduced for the first time concrete details of the new Eurofighter electronic combat role (ECR) concept. This role will enlarge Eurofighter’s multi-role capabilities and further increase the survivability of coalition forces in hostile environments.

Collaborative electronic warfare capabilities are essential for future combined air operations.

Initial Eurofighter ECR capability is expected to be available by 2026, followed by further development steps and full integration into the future combat air system (FCAS) ecosystems.

Eurofighter ECR will be able to provide passive emitter location as well as active jamming of threats, and will offer a variety of modular configurations for electronic attack (EA) and suppression/destruction of enemy air defence (SEAD/DEAD). Latest national escort jammer technology will ensure national control over features such as mission data and data analysis. The concept also features a new twin-seat cockpit configuration with a multi-function panoramic touch display and a dedicated mission cockpit for the rear-seat.

The concept is driven by the leading aerospace companies Airbus, Hensoldt, MBDA, MTU, Premium Aerotec, Rolls-Royce and supported by the German national industry bodies BDSV and BDLI. It specifically targets the German Air Force requirements for an airborne electronic attack capability. Furthermore it is the single opportunity to deliver such capabilities on the basis of national sovereignty, whilst also securing key military technologies within Germany.

Eurofighter is the backbone of German air defence. With more than 600 aircraft under contract and a workforce of 100.000 it is the largest collaborative defence programme in Europe to date.

The Typhoon is a highly agile aircraft at both supersonic and low speeds, achieved through having an intentionally relaxed stability design. It has a quadruplex digital fly-by-wire control system providing artificial stability, as manual operation alone could not compensate for the inherent instability. The fly-by-wire system is described as "carefree", and prevents the pilot from exceeding the permitted manoeuvre envelope. Roll control is primarily achieved by use of the wing elevons. Pitch control is by operation of the foreplanes and elevons, the yaw control is by rudder. Control surfaces are moved through two independent hydraulic systems, which also supply various other items, such as the canopy, brakes and undercarriage; powered by a 4,000 psi engine-driven pumps. Engines are fed by a chin double intake ramp situated below a splitter plate.

The Typhoon features lightweight construction (82% composites consisting of 70% carbon fibre composite materials and 12% glass fibre reinforced composites) with an estimated lifespan of 6,000 flying hours. The permitted lifespan, as opposed to the estimated lifespan, was 3,000 hours.

Radar signature reduction features

Although not designated a stealth fighter, measures were taken to reduce the Typhoon's radar cross section (RCS), especially from the frontal aspect. An example of these measures is that the Typhoon has jet inlets that conceal the front of the jet engine (a strong radar target) from radar. Many important potential radar targets, such as the wing, canard and fin leading edges, are highly swept, so will reflect radar energy well away from the front sector. Some external weapons are mounted semi-recessed into the aircraft, partially shielding these missiles from incoming radar waves. In addition radar-absorbent materials (RAM), developed primarily by EADS/DASA, coat many of the most significant reflectors, such as the wing leading edges, the intake edges and interior, the rudder surrounds, and strakes.

The manufacturers have carried out tests on the early Eurofighter prototypes to optimise the low observability characteristics of the aircraft from the early 1990s. Testing at BAE's Warton facility on the DA4 prototype measured the RCS of the aircraft and investigated the effects of a variety of RAM coatings and composites. Another measure to reduce the likelihood of discovery is the use of passive sensors (PIRATE IRST), which minimises the radiation of treacherous electronic emissions. While canards generally have poor stealth characteristics, the flight control system is designed to maintain the elevon trim and canards at an angle at which they have the smallest RCS.

Cockpit

The Typhoon features a glass cockpit without any conventional instruments. It incorporates three full colour multi-function head-down displays (MHDDs) (the formats on which are manipulated by means of softkeys, XY cursor, and voice (Direct Voice Input or DVI) command), a wide angle head-up display (HUD) with forward-looking infrared (FLIR), a voice and hands-on throttle and stick (Voice+HOTAS), a Helmet Mounted Symbology System (HMSS), a Multifunctional Information Distribution System (MIDS), a manual data-entry facility (MDEF) located on the left glareshield and a fully integrated aircraft warning system with a dedicated warnings panel (DWP). Reversionary flying instruments, lit by LEDs, are located under a hinged right glareshield. Access to the cockpit is normally via either a telescopic integral ladder or an external version. The integral ladder is stowed in the port side of the fuselage, below the cockpit.

User needs were given a high priority in the cockpit's design; both layout and functionality was created through feedback and assessments from military pilots and a specialist testing facility. The aircraft is controlled by means of a centre stick (or control stick) and left hand throttles, designed on a Hand on Throttle and Stick (HOTAS) principle to lower pilot workloads. Emergency escape is provided by a Martin-Baker Mk.16A ejection seat, with the canopy being jettisoned by two rocket motors. The HMSS was delayed by years but should have been operational by late 2011. Standard g-force protection is provided by the full-cover anti-g trousers (FCAGTs). a specially developed g suit providing sustained protection up to 9 g. German Air Force and Austrian Air Force pilots wear a hydrostatic g-suit called Libelle (dragonfly) Multi G Plus instead, which also provides protection to the arms, theoretically giving more complete g tolerance.

In the event of pilot disorientation, the Flight Control System allows for rapid and automatic recovery by the simple press of a button. On selection of this cockpit control the FCS takes full control of the engines and flying controls, and automatically stabilises the aircraft in a wings level, gentle climbing attitude at 300 knots, until the pilot is ready to retake control. The aircraft also has an Automatic Low-Speed Recovery system (ALSR) which prevents it from departing from controlled flight at very low speeds and high angle of attack. The FCS system is able to detect a developing low-speed situation and to raise an audible and visual low-speed cockpit warning. This gives the pilot sufficient time to react and to recover the aircraft manually. If the pilot does not react, however, or if the warning is ignored, the ALSR takes control of the aircraft, selects maximum dry power for the engines and returns the aircraft to a safe flight condition. Depending on the attitude, the FCS employs an ALSR "push", "pull" or "knife-over" manoeuvre.

The Typhoon Direct Voice Input (DVI) system uses a speech recognition module (SRM), developed by Smiths Aerospace (now GE Aviation Systems) and Computing Devices (now General Dynamics UK). It was the first production DVI system used in a military cockpit. DVI provides the pilot with an additional natural mode of command and control over approximately 26 non-critical cockpit functions, to reduce pilot workload, improve aircraft safety, and expand mission capabilities. An important step in the development of the DVI occurred in 1987 when Texas Instruments completed the TMS-320-C30, a digital signal-processor, enabling reductions in the size and system complexity required. The project was given the go-ahead in July 1997, with development and pilot assessment carried out on the Eurofighter Active Cockpit Simulator at BAE Systems Warton.

The DVI system is speaker-dependent, requiring each pilot to create a template. It is not used for safety-critical or weapon-critical tasks, such as weapon release or lowering of the undercarriage, but is used for a wide range of cockpit functions. Voice commands are confirmed by visual or aural feedback, and serves to reduce pilot workload. All functions are also achievable by means of a conventional button-press or soft-key selections; functions include display management, communications, and management of various systems. EADS Defence and Security in Spain has worked on a new non-template DVI module to allow for continuous speech recognition, speaker voice recognition with common databases (e.g. British English, American English, etc.) and other improvements.

Avionics

Navigation is via both GPS and an inertial navigation system. The Typhoon can use Instrument Landing System (ILS) for landing in poor weather. The aircraft also features an enhanced ground proximity warning system (GPWS) based on the TERPROM Terrain Referenced Navigation (TRN) system used by the Panavia Tornado. The Multifunctional Information Distribution System (MIDS) provides a Link 16 data link.

The aircraft employs a sophisticated and highly integrated Defensive Aids Sub-System named Praetorian (formerly called EuroDASS). Praetorian monitors and responds automatically to air and surface threats, provides an all-round prioritised assessment, and can respond to multiple threats simultaneously. Threat detection methods include a Radar warning receiver (RWR), a missile warning system (MWS) and a laser warning receiver (LWR, only on UK Typhoons). Protective countermeasures consist of chaff, flares, an electronic countermeasures (ECM) suite and a towed radar decoy (TRD). The ESM-ECM and MWS consists of 16 AESA antenna array assemblies and 10 radomes.

Traditionally each sensor in an aircraft is treated as a discrete source of information; however this can result in conflicting data and limits the scope for the automation of systems, hence increasing pilot workload. To overcome this, the Typhoon employs what are now known as sensor fusion techniques. In the Typhoon fusion of all data sources is achieved through the Attack and Identification System, or AIS. The AIS combines data from the major on-board sensors along with any information obtained from off-board platforms such as AWACS, ASTOR, and Eurofighter own Multifunctional Information Distribution System (MIDS). Additionally the AIS integrates all the other major offensive and defensive systems such as the DASS, Navigation, ACS and Communications. The AIS physically comprises two essentially separate units: the Attack Computer (AC) and the Navigation Computer (NC), linked via the STANAG 3910 databus to the other major systems such as the ACS, ECR-90/CAPTOR, PIRATE, etc. Both the AC and NC are identical in design, being a modular unit based on Motorola 68020 CPUs with 68882 Maths co-processors, as well as several custom RISC-based processors utilised to accelerate floating point and matrix operations.

By having a single source of information, pilot workload should be reduced by removing the possibility of conflicting data and the need for cross-checking, improving situational awareness and increasing systems automation. In practice the AIS should allow the Eurofighter to identify targets at distances in excess of 150 nmi and acquire and auto-prioritise them at over 100 nmi. In addition the AIS offers the ability to automatically control emissions from the aircraft, so called EMCON (from EMissions CONtrol). This should aid in limiting the detectability of the Typhoon by opposing aircraft further reducing pilot workload.

In 2017 a RAF Eurofighter Typhoon demonstrated interoperability with the F-35B using its Multifunction Advanced Data Link (MADL) in a two-week trial known as Babel Fish III, in the Mojave Desert. This was achieved by translating the MADL messages into Link 16 format, thus allowing a F-35 in stealth mode to communicate directly with the Typhoon.

Radar and sensors

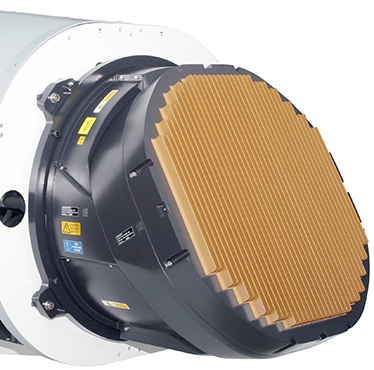

CAPTOR radar

The Eurofighter operates automatic Emission Controls (EMCON) to reduce the electro-magnetic emissions of the current CAPTOR mechanically scanned radar. The Captor-M has three working channels, one intended for classification of jammer and for jamming suppression. A succession of radar software upgrades have enhanced the air-to-air capability of the Captor-M radar. These upgrades have included the R2P programme (initially UK only, and known as T2P when 'ported' to the Tranche 2 aircraft) which is being followed by R2Q/T2Q. R2P was applied to eight German Typhoons deployed on Red Flag Alaska in 2012.

The CAPTOR-E is an active electronically scanned array derivative of the original CAPTOR radar, also known as CAESAR (from CAPTOR Active Electronically Scanned Array Radar) being developed by the EuroRADAR Consortium, led by Selex ES. The German BW-Plan 2009 indicated that Germany intended to equip/retrofit their Eurofighters with the AESA Captor-E from 2012, but the contract award was delayed until at least mid-2014.

Synthetic Aperture Radar is expected to be fielded as part of the AESA radar upgrade which will give the Eurofighter an all-weather ground attack capability. The conversion to AESA will also give the Eurofighter a low probability of intercept radar with much better jam resistance. These include an innovative design with a gimbal to meet RAF requirements for a wider scan field than a fixed AESA. The coverage of a fixed AESA is limited to 120° in azimuth and elevation. A senior EADS radar expert has claimed that Captor-E is capable of detecting an F-35 from roughly 59 km away.

In May 2007, Eurofighter Development Aircraft 5 made the first flight with the CAPTOR-E demonstrator system, Tranche 2 aircraft use the non-AESA mechanically scanned Captor-M which incorporates weight and space provisions for possible upgrade to CAESAR (AESA) standard in the future. In June 2013, Chris Bushell of Selex ES warned that the failure of European nations to invest in an AESA radar was putting export orders at risk. In November BAE responded that work on an AESA radar continued, to protect exports. On 22 June 2011, it was announced that the partner nations had agreed to fund development of the Captor-E radar, with entry into service planned for 2015. The British are pursuing an independent Technology Demonstrator Programme called Bright Adder, which will give the Typhoon an Electronic Attack mode among other things. Bright Adder is based on Qinetiq's ARTS radar demonstrator for the Tornado GR4 and could evolve into an alternative to the main E-Scan project should E-Scan falter.

The first flight of a Eurofighter equipped with a "mass model" of the Captor-E occurred in late February 2014, with flight tests of the actual radar beginning in July of that year. Tranche 3 Typhoons have the mechanical, electrical and cooling enhancements needed to operate the radar. At the 2014 Farnborough Airshow the UK MOD announced that it had awarded BAE Systems a £72 million ($124 million) contract to conduct national-specific testing on a prototype AESA system. On 19 November 2014 the contract to upgrade to the Captor-E was signed at the offices of EuroRadar lead Selex ES in Edinburgh, in a deal worth €1bn. Availability of the radar, for Tranche 2 and 3A aircraft, was anticipated by 2016–17, but there are no orders for the radar system from the partner nations. However, Kuwait became the launch customer for the Captor-E active electronically scanned array radar in April 2016.

Germany's Luftwaffe have announced the intention to integrate the AESA Captor-E into their Typhoons, beginning in 2022.

IRST

The Passive Infra-Red Airborne Track Equipment (PIRATE) system is an infrared search and track (IRST) system mounted on the port side of the fuselage, forward of the windscreen. Selex ES is the lead contractor which, along with Thales Optronics (system technical authority) and Tecnobit of Spain, make up the EUROFIRST consortium responsible for the system's design and development. Eurofighters starting with Tranche 1 block 5 have the PIRATE. The first Eurofighter Typhoon with PIRATE-IRST was delivered to the Italian Aeronautica Militare in August 2007. More advanced targeting capabilities can be provided with the addition of a targeting pod such as the LITENING pod.

PIRATE operates in two IR bands, 3–5 and 8–11 micrometres. When used with the radar in an air-to-air role, it functions as an infrared search and track system, providing passive target detection and tracking. In an air-to-surface role, it performs target identification and acquisition. By supercooling the sensor, the system can detect even small variations in temperature at a long range. Although no definitive ranges have been released, an upper limit of 80 nmi has been hinted at; a more typical figure would be 30 to 50 nmi. It also provides a navigation and landing aid. PIRATE is linked to the pilot's helmet-mounted display. It allows the detection of both hot exhaust plumes of jet engines and surface heating caused by friction; processing techniques further enhance the output, giving a near-high resolution image of targets. The output can be directed to any of the Multi-function Head Down Displays, and can also be overlaid on both the Helmet Mounted Sight and Head Up Display.

The IIR sensor has a stabilised mount so that it can maintain a target within its field of view. Up to 200 targets can be simultaneously tracked using one of several different modes; Multiple Target Track (MTT), Single Target Track (STT), Single Target Track Ident (STTI), Sector Acquisition and Slaved Acquisition. In MTT mode the system will scan a designated volume space looking for potential targets. In STT mode PIRATE will provide high precision tracking of a single designated target. An addition to this mode, STT Ident allows for visual identification of the target, the resolution being superior to CAPTOR's. Both Sector and Slave Acquisition demonstrate the level of sensor fusion present in the Typhoon. When in Sector Acquisition mode PIRATE will scan a volume of space under direction of another onboard sensor such as CAPTOR. In Slave Acquisition, off-board sensors are used with PIRATE being commanded by data obtained from an AWACS or other source. When a target is found in either of these modes, PIRATE will automatically designate it and switch to STT.

Once a target has been tracked and identified, PIRATE can be used to cue an appropriately equipped short range missile, i.e. a missile with a high off-boresight tracking capability such as ASRAAM. Additionally the data can be used to augment that of CAPTOR or off-board sensor information via the AIS. This should enable the Typhoon to overcome severe ECM environments and still engage its targets. PIRATE also has a passive ranging capability although the system remains limited when providing passive firing solutions, as it does not have a laser rangefinder.

Engines

The Eurofighter Typhoon is fitted with two Eurojet EJ200 engines, each capable of providing up to 60 kN (13,500 lbf) of dry thrust and >90 kN (20,230 lbf) with afterburners. Using the ‘war’ setting, dry thrust increases by 15% to 69 kN per engine and afterburners by 5% to 95 kN per engine and for a few seconds, up to 102 kN thrust without damaging the engine. The EJ200 engine combines the leading technologies from each of the four European companies, using advanced digital control and health monitoring; wide chord aerofoils and single crystal turbine blades; and a convergent / divergent exhaust nozzle to give excellent thrust-to-weight ratio, multimission capability, supercruise performance, low fuel consumption, low cost of ownership, modular construction and significant growth potential.

The Typhoon is capable of supersonic cruise without using afterburners (referred to as supercruise). Air Forces Monthly gives a maximum supercruise speed of Mach 1.1 for the RAF FGR4 multirole version, however in a Singaporean evaluation, a Typhoon managed to supercruise at Mach 1.21 on a hot day with a combat load. The Eurofighter Company states that the Typhoon can supercruise at Mach 1.5. As with the F-22, the Eurofighter can launch weapons while under supercruise to extend their ranges via this "running start".

In 2007, the EJ200 engine had accumulated 50,000 Engine Flying Hours in service with the four Nation Air Forces (Germany, UK, Spain and Italy).

In addition to the potential for increases in thrust of up to 30%, the EJ200 engine has the potential to be fitted with Thrust Vectoring Nozzles (TVN), that the Eurofighter and Eurojet consortium have been actively developing and testing, primarily for export, but also for future upgrades of the fleet. TVN could reduce fuel burn on a typical Typhoon mission by up to 5%, as well as increase available thrust in supercruise by up to 7% and take-off thrust by 2%.

Clemens Linden, Eurojet TURBO GmbH CEO, speaking at the 2018 Farnborough International Air Show, said "15 per cent more thrust would allow pilots to operate with a heavily loaded aircraft in the battlespace with the same performance levels as they have today. The technology insertion also provides more persistence — giving aircraft longer range or longer loitering time. To achieve more thrust we would increase the airflow and pressure ratios of the high and low pressure compressors and run higher temperatures in the turbines by using the latest generation single crystal turbine blade materials. And with higher aerodynamic efficiencies we can achieve a lower fuel burn. A third area of improvement would be the engine exhaust nozzle which would be upgraded with the installation of a 2-parametric version allowing independent and optimized adjustment of the throat and exit area at all flight conditions, providing fuel burn advantages. The technologies for the different components are at a Technology Readiness Level of between 7 and 9. The nozzle has been at ITP in Spain on a test bed for 400 hours.”

Performance

The Typhoon's combat performance, compared to the F-22 Raptor and F-35 Lightning II fighters and the French Dassault Rafale, has been the subject of much discussion. In March 2005, United States Air Force Chief of Staff General John P. Jumper, then the only person to have flown both the Eurofighter Typhoon and the Raptor, talked to Air Force Print News about these two aircraft. He said,

The Eurofighter is both agile and sophisticated, but is still difficult to compare to the F/A-22 Raptor. They are different kinds of airplanes to start with; it's like asking us to compare a NASCAR car with a Formula One car. They are both exciting in different ways, but they are designed for different levels of performance. …The Eurofighter is certainly, as far as smoothness of controls and the ability to pull (and sustain high G forces), very impressive. That is what it was designed to do, especially the version I flew, with the avionics, the color moving map displays, etc. – all absolutely top notch. The maneuverability of the airplane in close-in combat was also very impressive. The F/A-22 performs in much the same way as the Eurofighter. But it has additional capabilities that allow it to perform the [U.S.] Air Force's unique missions.

In the 2005 Singapore evaluation, the Typhoon won all three combat tests, including one in which a single Typhoon defeated three RSAF F-16s, and reliably completed all planned flight tests. In July 2009, Former Chief of Air Staff for the Royal Air Force, Air Chief Marshal Sir Glenn Torpy, said that "The Eurofighter Typhoon is an excellent aircraft. It will be the backbone of the Royal Air Force along with the JSF".

In July 2007, Indian Air Force Su-30MKI fighters participated in the Indra-Dhanush exercise with the Royal Air Force's Typhoon. This was the first time that the two fighters had taken part in such an exercise. The IAF did not allow their pilots to use the MKI's radar during the exercise to protect the highly classified Russian N011M Bars. The IAF pilots were impressed by the Typhoon's agility.

In 2015, Indian Air Force Su-30MKIs participated in the Indra-Dhanush exercise with Royal Air Force Typhoons. At the end of this exercise, the IAF claimed they had "beaten" the RAF 12-0 in WVR engagements, however this claim was disputed by an RAF source quoted by the Independent as "clearly designed for a domestic audience", a position also supported by the UK Ministry of Defence and Royal Air Force making these statements respectively: "As you would expect, advanced military capabilities are rarely operated to the limits of their potential, especially when exercising against other nations’ aircraft. This exercise was no exception for the Typhoon Force", and "Our analysis does not match what has been reported, RAF pilots and the Typhoon performed well throughout the exercise with and against the Indian Air Force. Both forces learnt a great deal from the exercise and the RAF look forward to the next opportunity to train alongside the IAF." When asked about the results of the 4 vs 4 and 8 vs 8 BVR engagements the Indian Air Force spokesman refused to comment saying only 'It was not unexpected for the IAF to “lose” one or two jets'.

(Web, Google, Wikipedia, Airbus, You Tube)